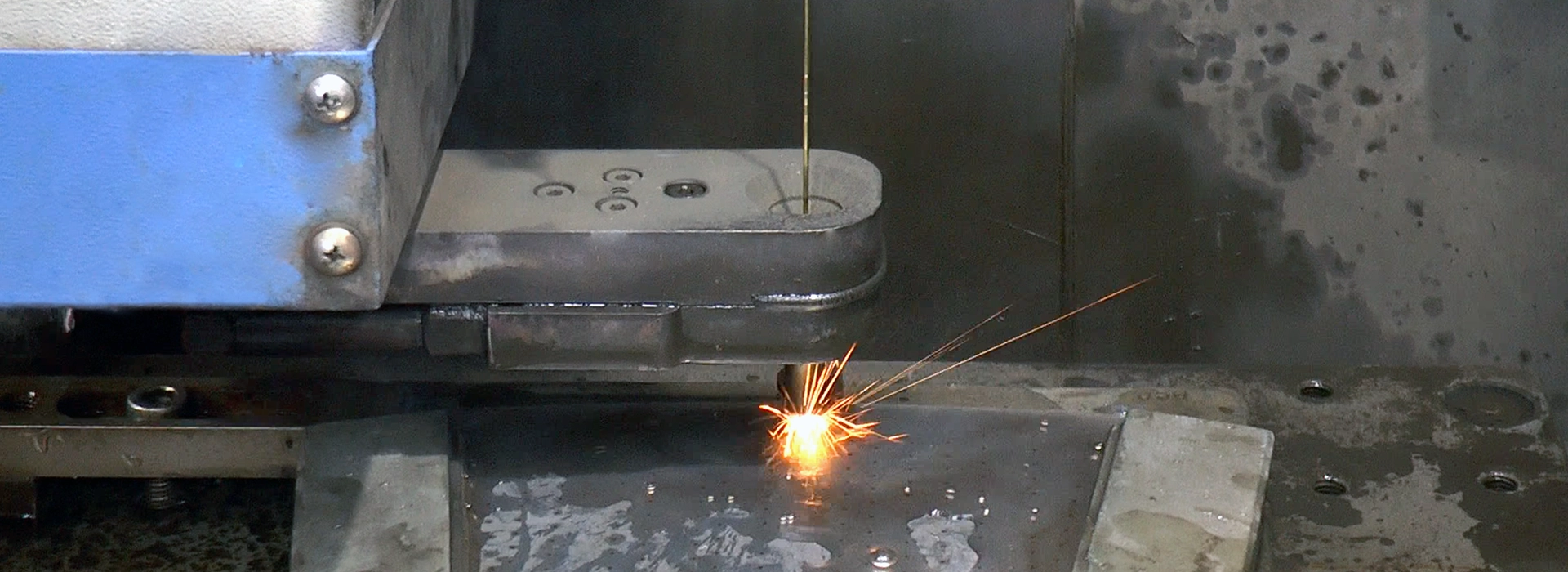

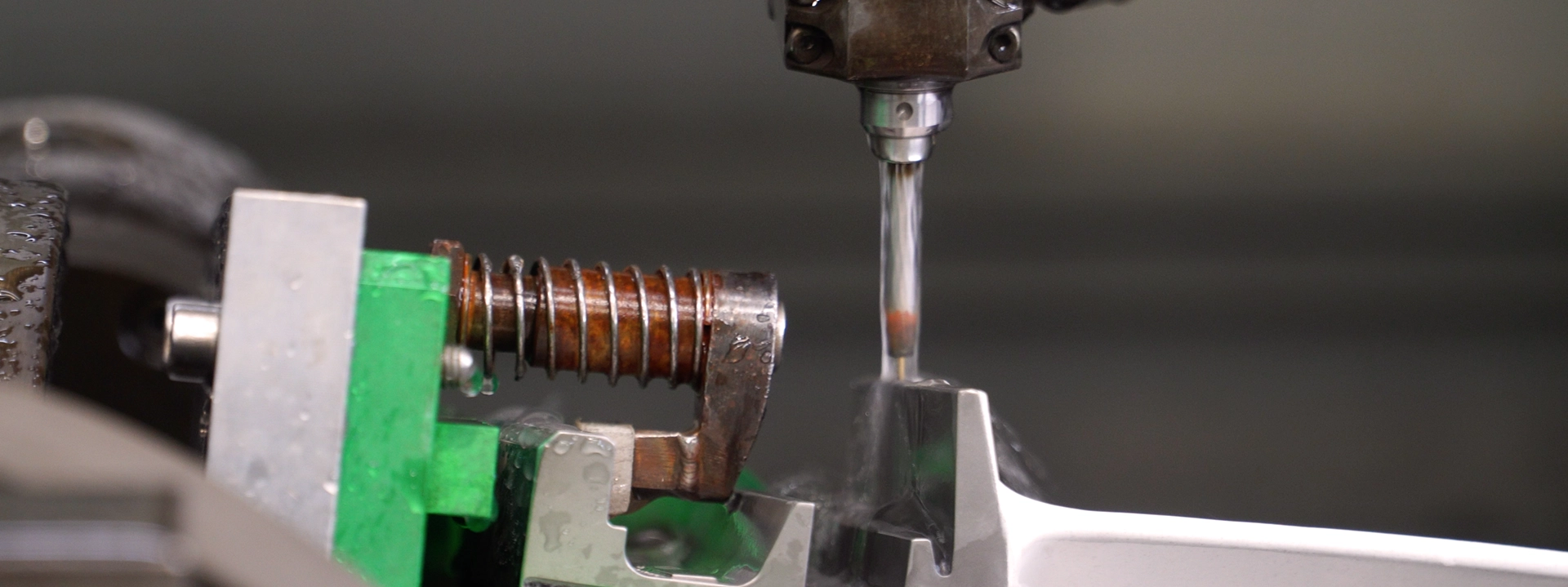

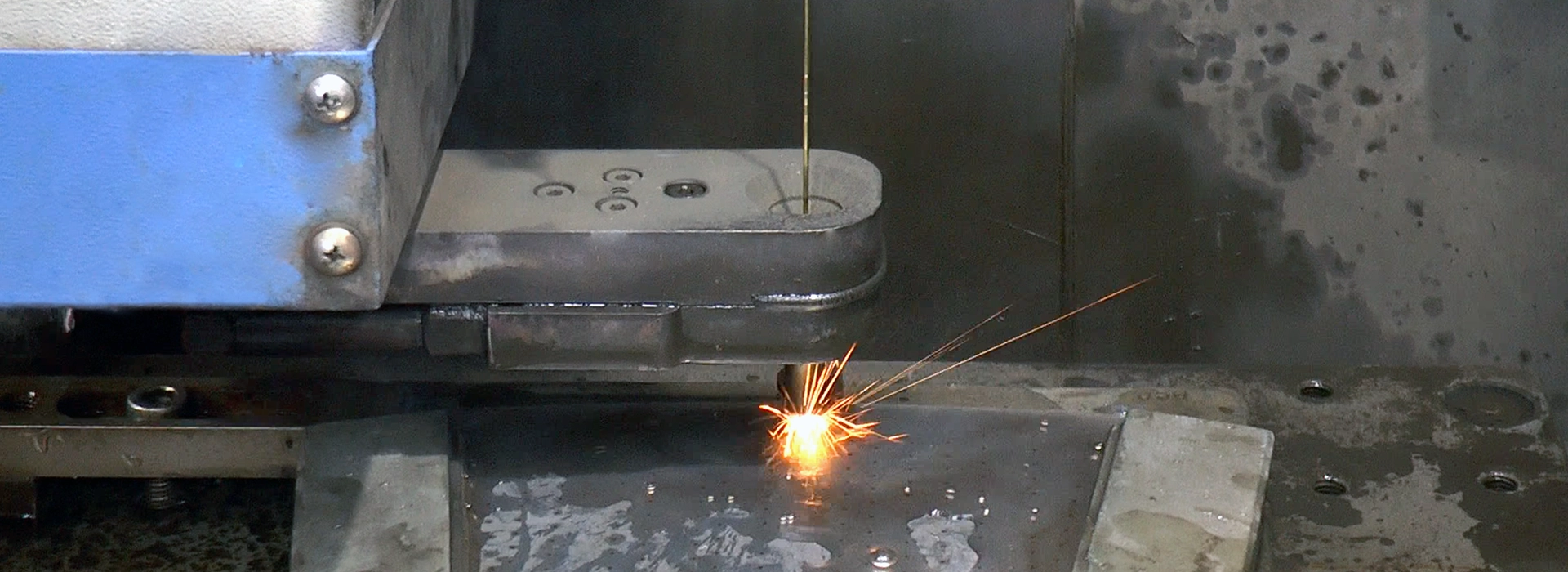

SILMEC is equipped with CNC wire EDM machines capable of 5-axis movement with continuous wire feed systems. We work in accordance with international quality standards and can guarantee reliable and safe machining. The 5-axis configuration allows us to significantly increase flexibility, enabling complex machining in 3 dimensions:

These features allow us to create:

The high precision of this machining, which allows tolerances in the order of a few microns, and achieves extremely low surface roughness without the need for additional finishing, offers numerous advantages for many industrial contexts:

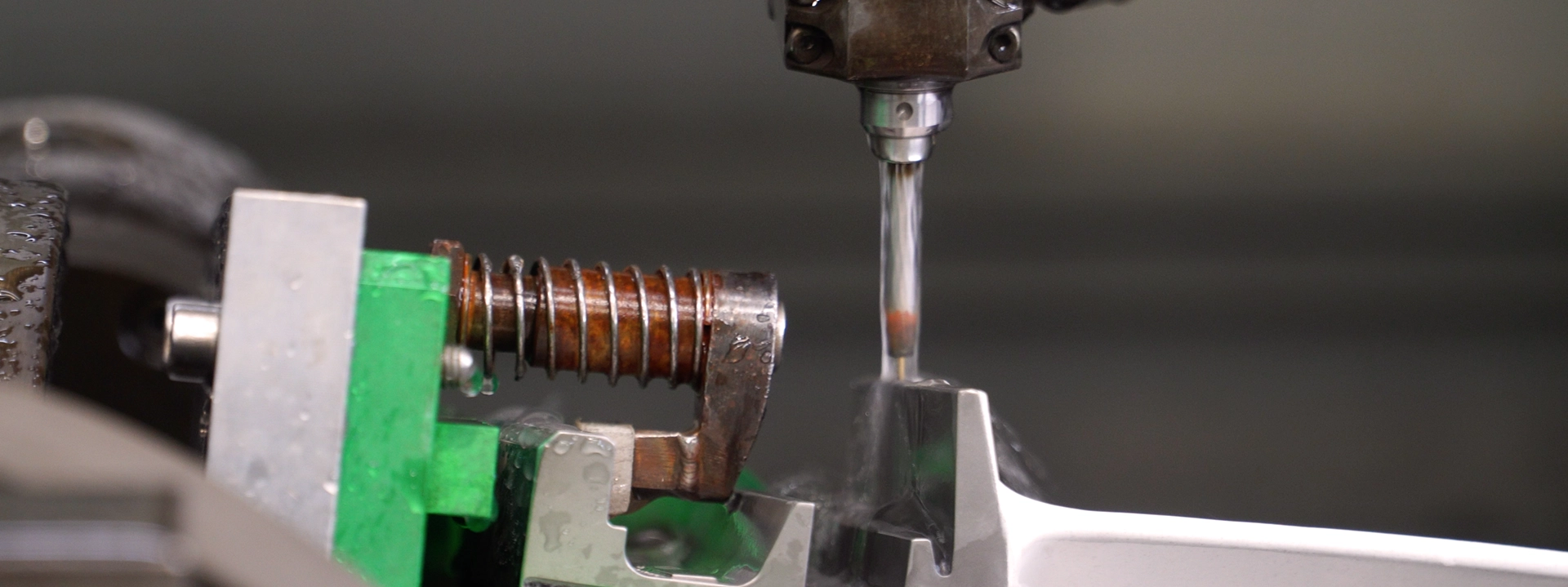

Microscopic drilling with extremely tight tolerances in gas turbine blades and segments. The precision of micro-holes enhances airflow management and cooling, increasing turbine lifespan and efficiency.

Micro-holes on turbine blades: the network of micro-holes ensures a precise flow of cooling air, improving thermal resistance and component durability. The same principle applies to micro-holes in actuators and valves, which regulate the flow of hydraulic fluids or gas to ensure precise movement of components.

Machining of piezoelectric ultrasonic inserts used in advanced surgical and diagnostic instruments. EDM-drilled inserts enhance the performance of ultrasonic instruments used in surgery and diagnostics.

More than 20 years expertise on EDM Machining

Use of 5-axis CNC machines to ensure precision and quality.

Ability to handle both large-scale production and customized projects.

Quality controls and compliance with international standards.

Continuous investment in research and development to improve technologies and performance.

Our production organization ensures short delivery lead times.