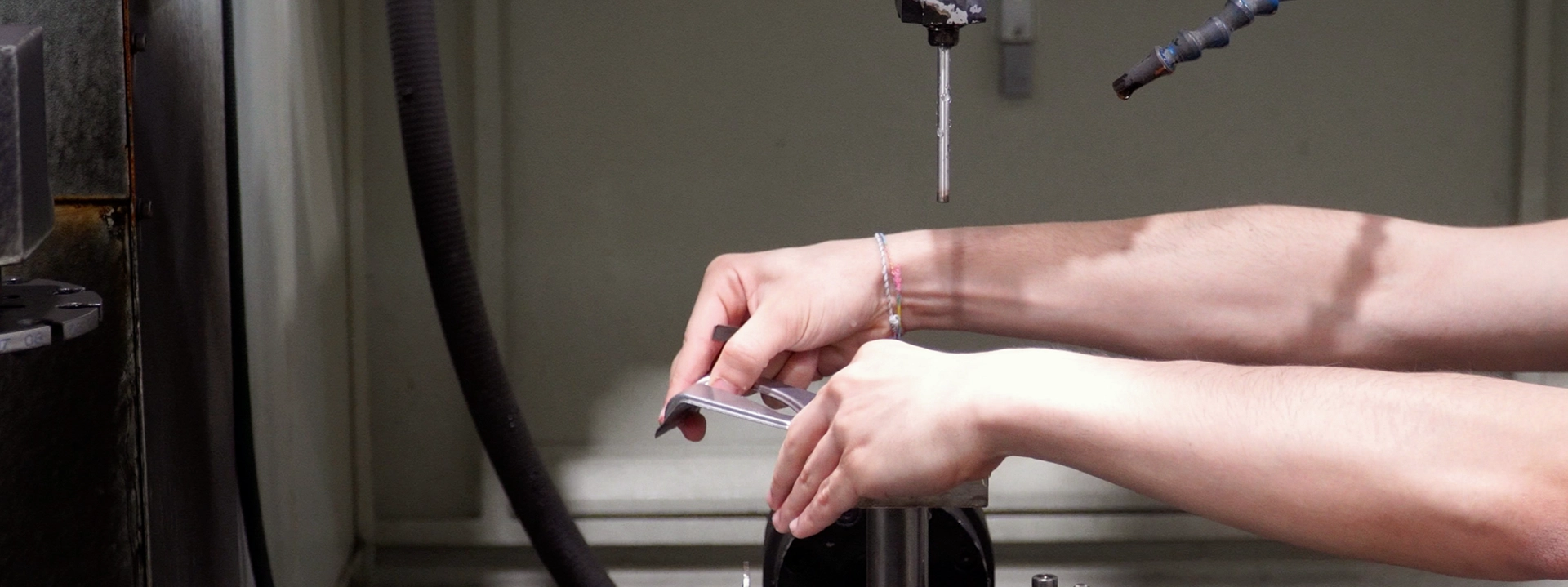

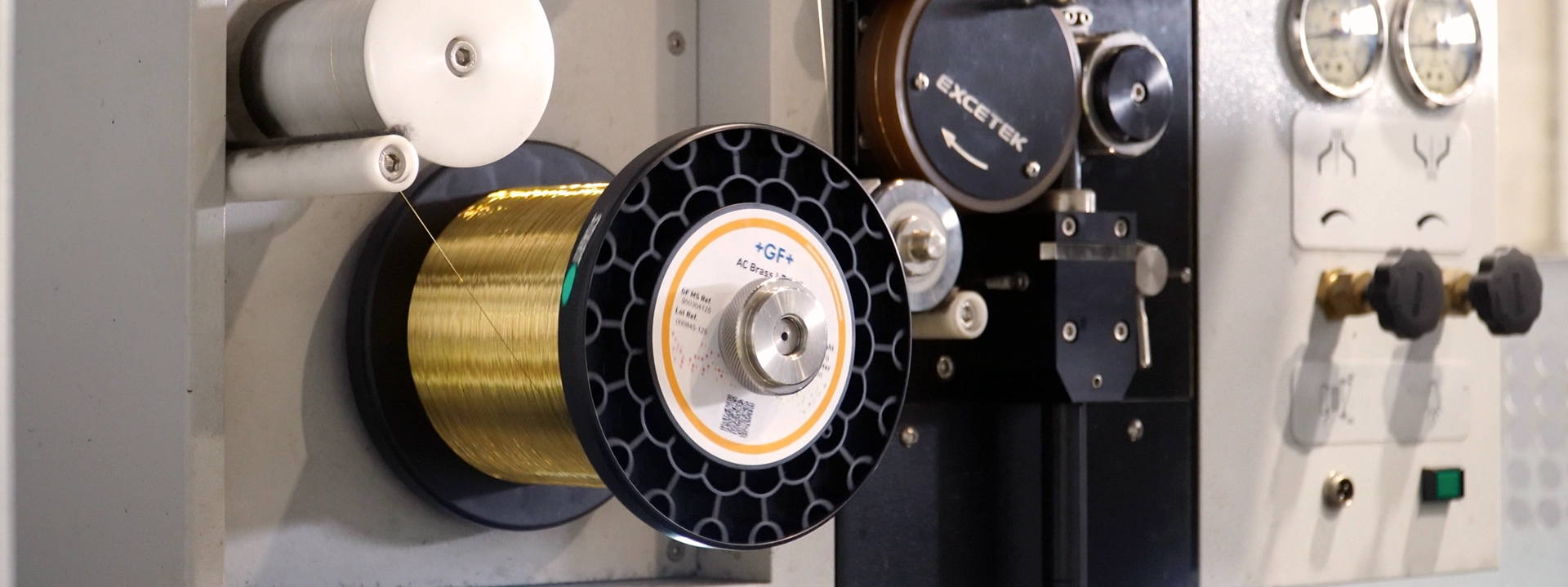

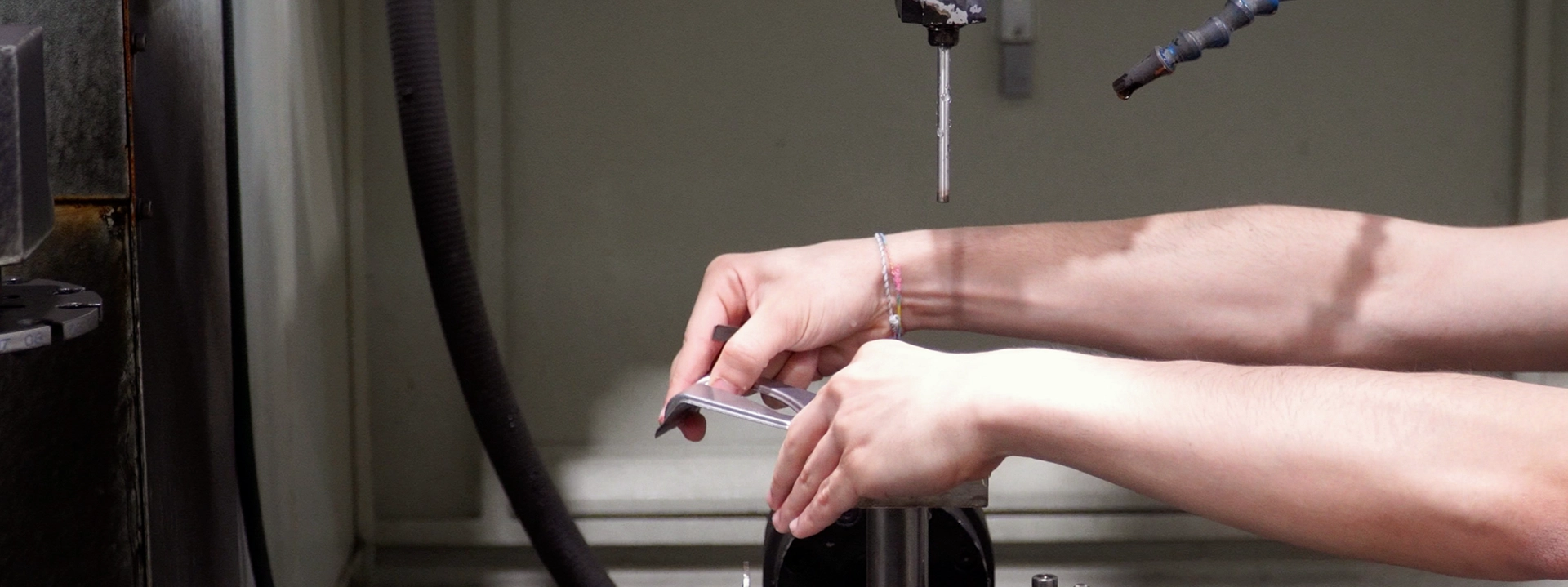

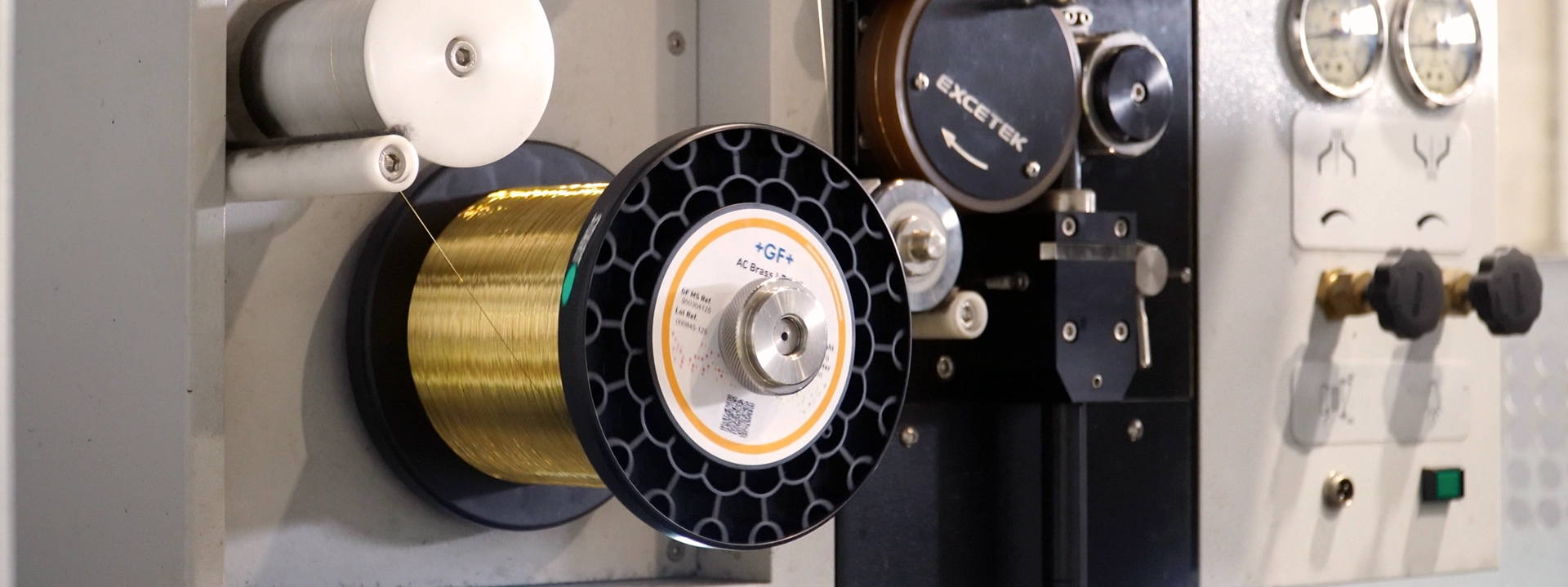

SILMEC is equipped with CNC wire EDM machines capable of operating with 5-axis movement and continuous wire feeding systems. We work in compliance with international quality standards, ensuring reliable and safe products.

The exceptional precision of this process, allowing for micron-level tolerances and extremely low surface roughness without additional finishing, offers numerous advantages across various industries:

Microscopic drilling with extremely tight tolerances for gas turbine blades and segments.

Components for combustion chambers, turbine blades, precision gears, discs, and hubs.

Machining of piezoelectric ultrasonic inserts used in advanced surgical and diagnostic instruments.

High-precision gas turbine components, improving efficiency and durability.

Collaboration with industry leaders to manufacture complex engine components.

Development of advanced surgical instruments with tight tolerances and flawless surface finishes.

Over 20 years of experience in EDM machining.

Utilization of 5-axis CNC machines to ensure high precision and quality.

Ability to handle both large-scale production and customized projects.

Strict quality controls and compliance with international standards.