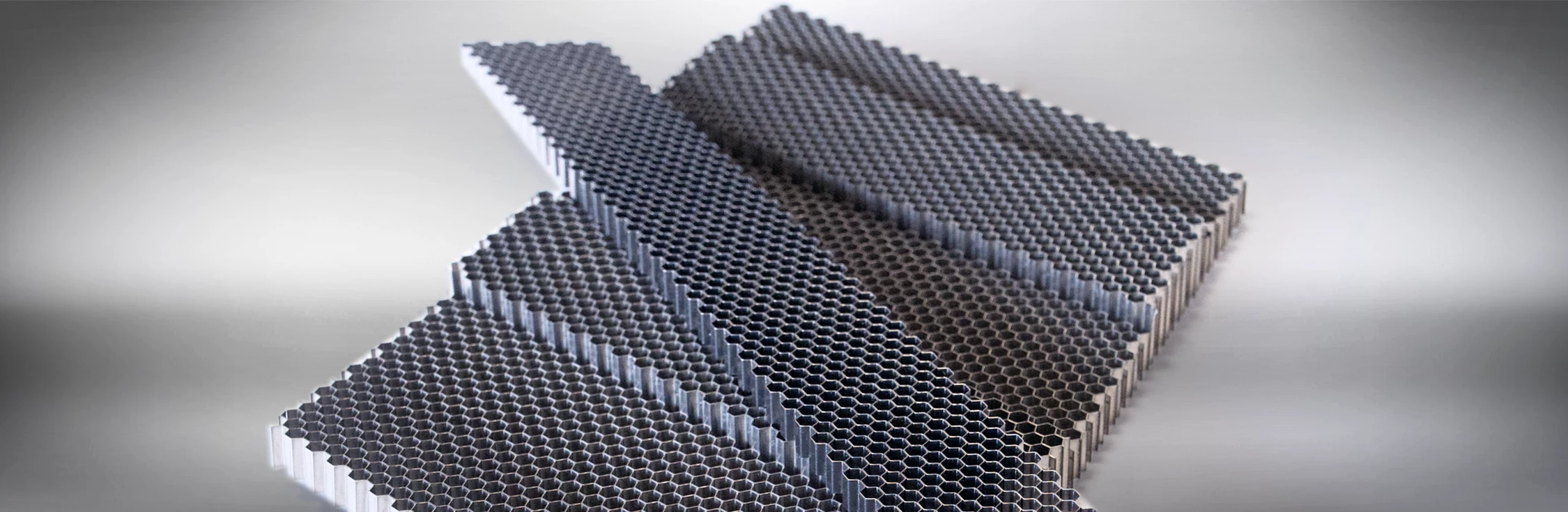

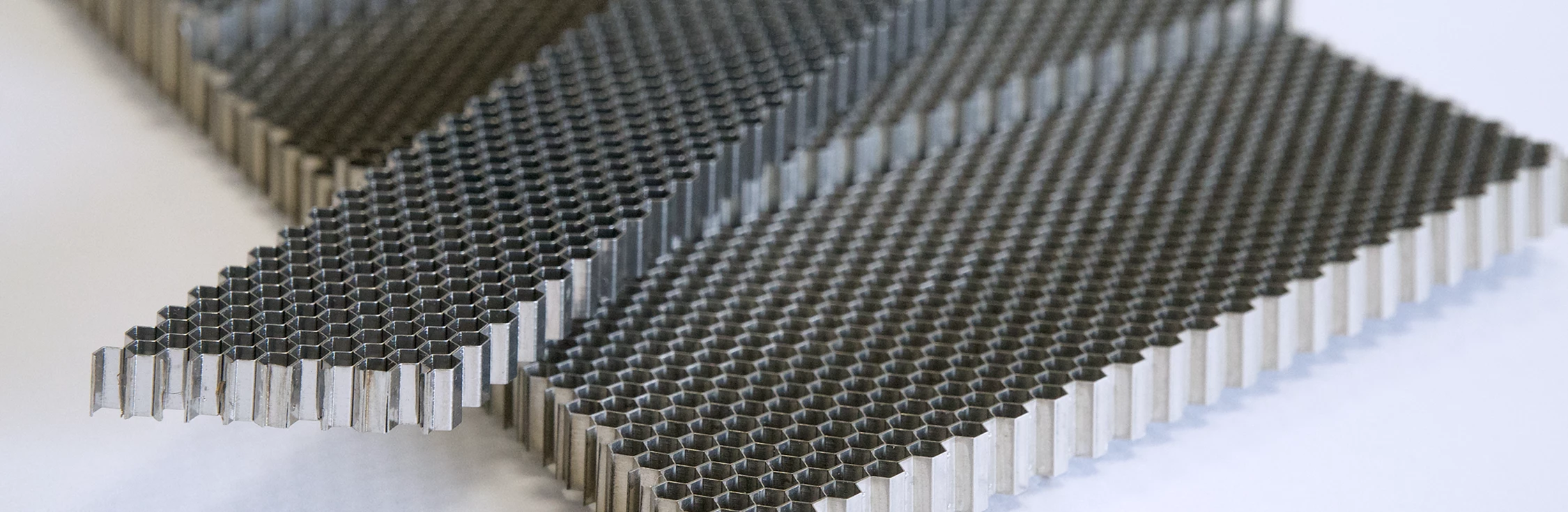

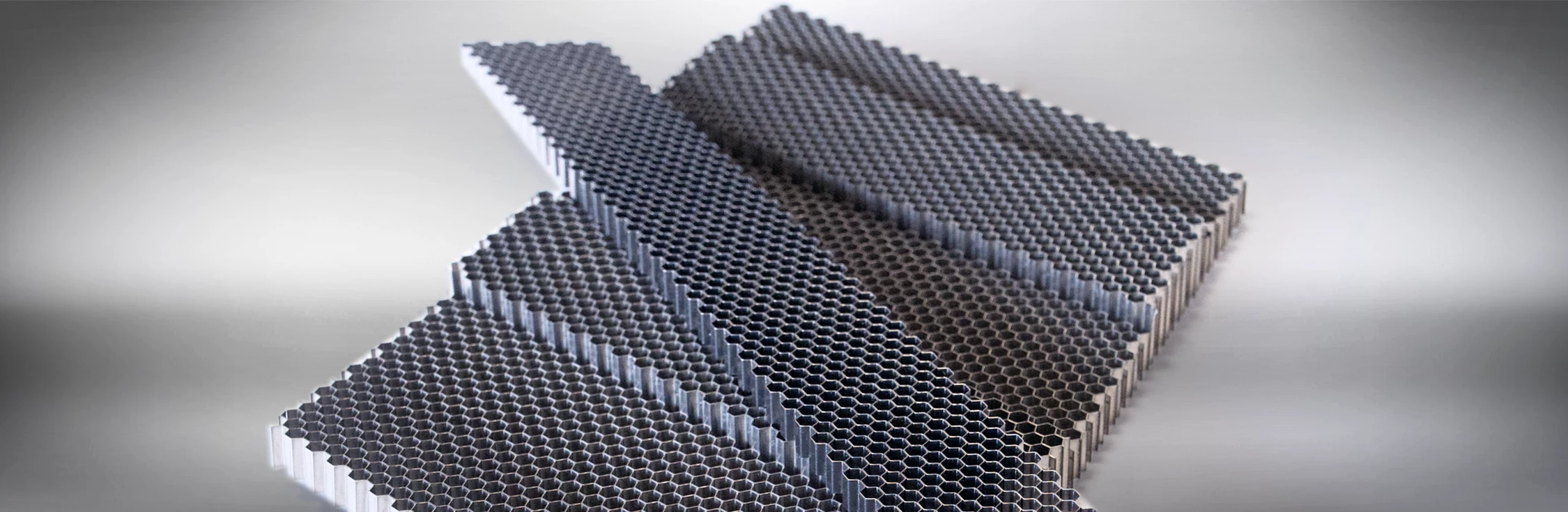

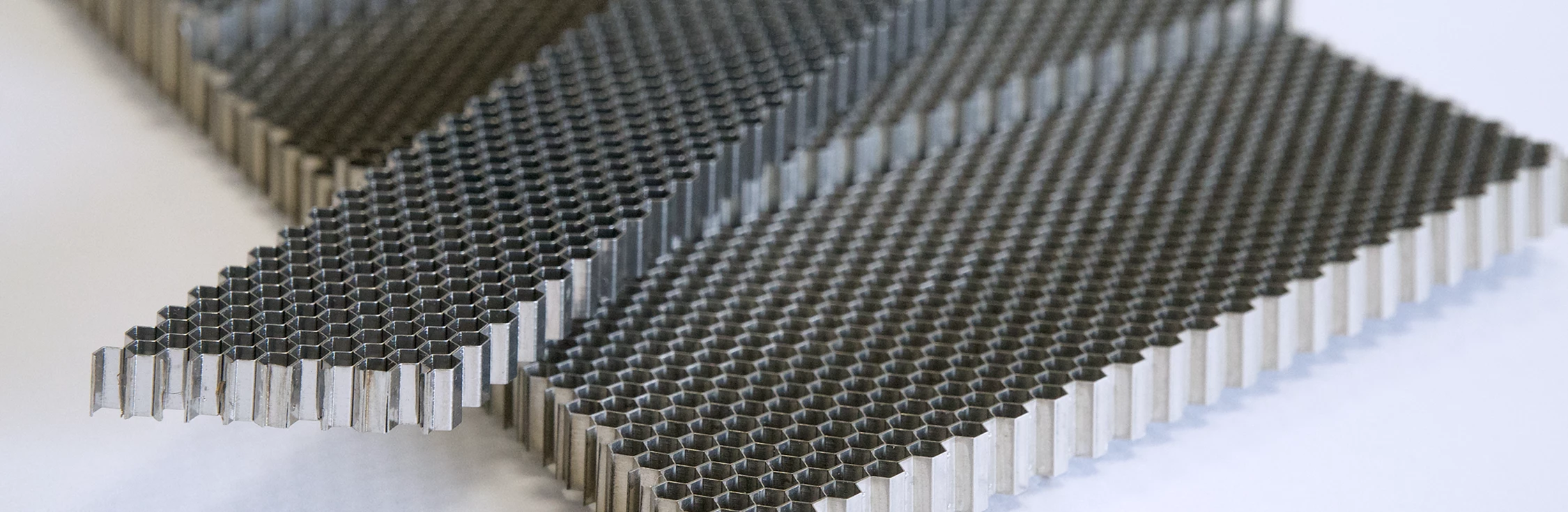

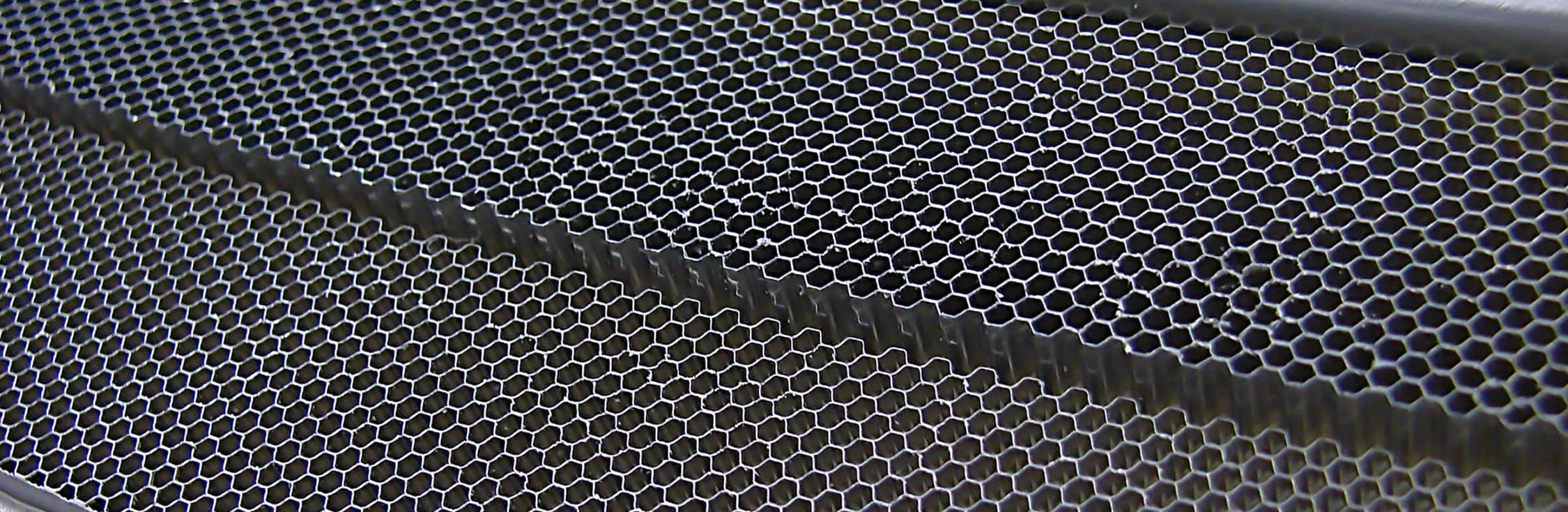

Honeycomb Cores are made from super alloys, which are used in many applications due to their excellent combination of lightness and strength. These components are essential in strategic sectors requiring high-performance materials, such as the aerospace and power generation industries.

Materials |

Hexagonal cell dimensions |

|---|---|

Hastelloy-x |

0,4 mm |

Haynes-214 |

0,78 mm |

Haynes-224 |

1,57 mm |

Haynes-230 |

2,38 mm |

Haynes-233 |

3,17 |

Stainless steel |

4,77 |

Hastelloy-s |

|

Inconel |

|

|

|

|

Material Thickness |

0,025 – 2,8 mm |

Welding capacity on a cell |

1-2 points |

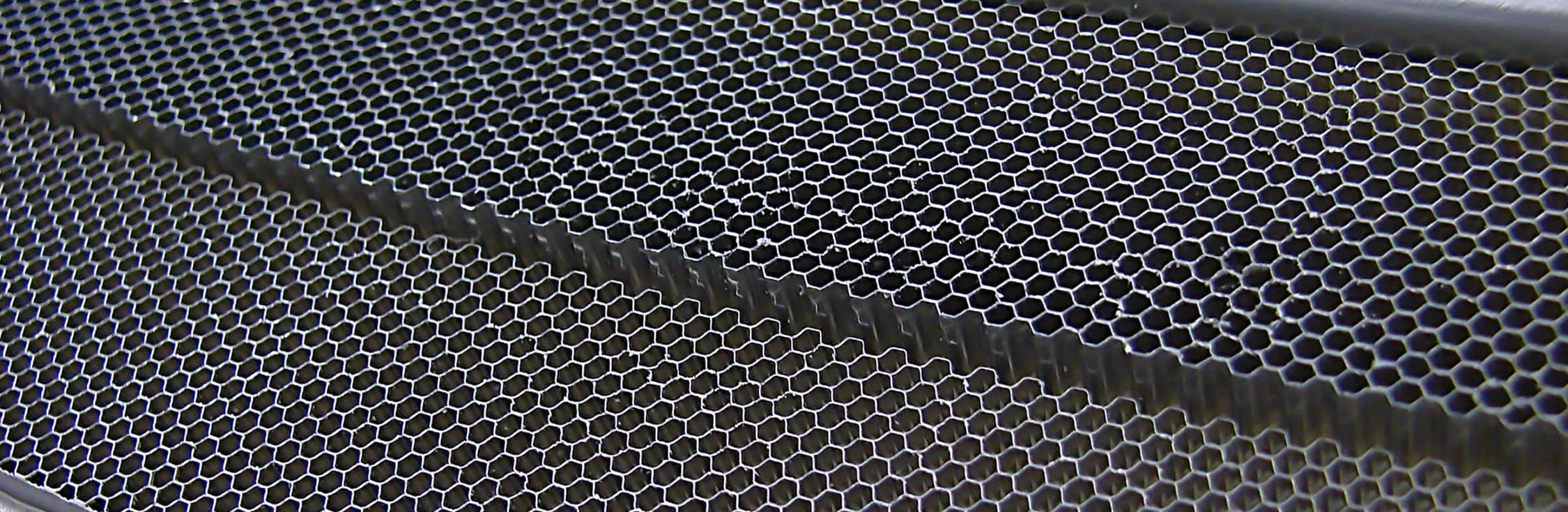

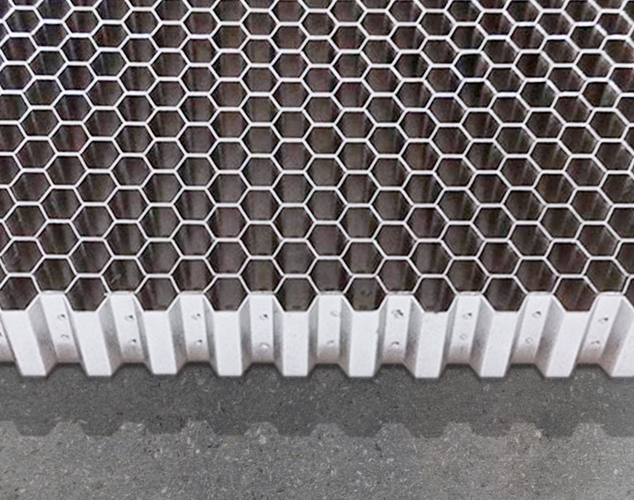

In the production of Honeycomb, for special requirements and industrial contexts, we can perform the application of a brazing paste mat on the manufactured components. The tape is cut and positioned to size.

the pre-embedded brazing tape makes Honeycomb products ready to use. It avoids the application of brazing paste, thus reducing processing time.

the use of pre-embedded tapes allows more precise and controlled distribution, reducing the risk of waste compared to other less precise manual methods of applying brazing paste.

brazing tapes reduce the need for complex heat treatment, the use of harmful chemicals for surface treatment and exposure for operators. This also means less environmental impact and fewer health risks.

The requirements for the pre-embedded brazing tapes we use refer to the AMS-4777 / AMS-4778 / AMS-4779 / AMS-4782 / AMDRY-103 / AMDRY specifications that define the chemical, physical and mechanical characteristics needed to cope with the high strength, high temperature and durability conditions required by particular strategic industries.

reducing the overall weight of structures without compromising strength.

ability to operate in extreme environments while maintaining structural stability.

tailor-made solutions to meet the specific needs of each customer.

high quality materials that ensure long component life.

as the only manufacturer in Italy, we can guarantee very short lead times, minimising waiting times for our customers.

components for gas and steam turbines, improving energy efficiency and reducing operating costs..

light and strong parts for aircraft and spacecraft, contributing to superior performance and safety.

applications in industrial furnaces, process equipment and high-performance exhaust systems.